Sept. 24, 2024

BENEFITS OF MICROWAVE DRYING

PART 1 – CONVECTION DRYING AND VERSATILITY OF DIELECTRIC DRYING

When choosing a drying system, it’s important to have a clear understanding of the techniques available. From the process of making healthy snacks in your pantry to the foam of the chair you’re sitting on, drying is a key step during production. Finding the right drying technique that balances efficiency and cost, depends both on the material and the end goal. For instance, a material could be dried to increase product quality, reduce shipping weight, or stop mold and bacteria growth. To gain a better understanding of the differences between convection and microwave drying, let’s compare each drying technique, their operations, and possible end-product.

MOISTURE REMOVAL

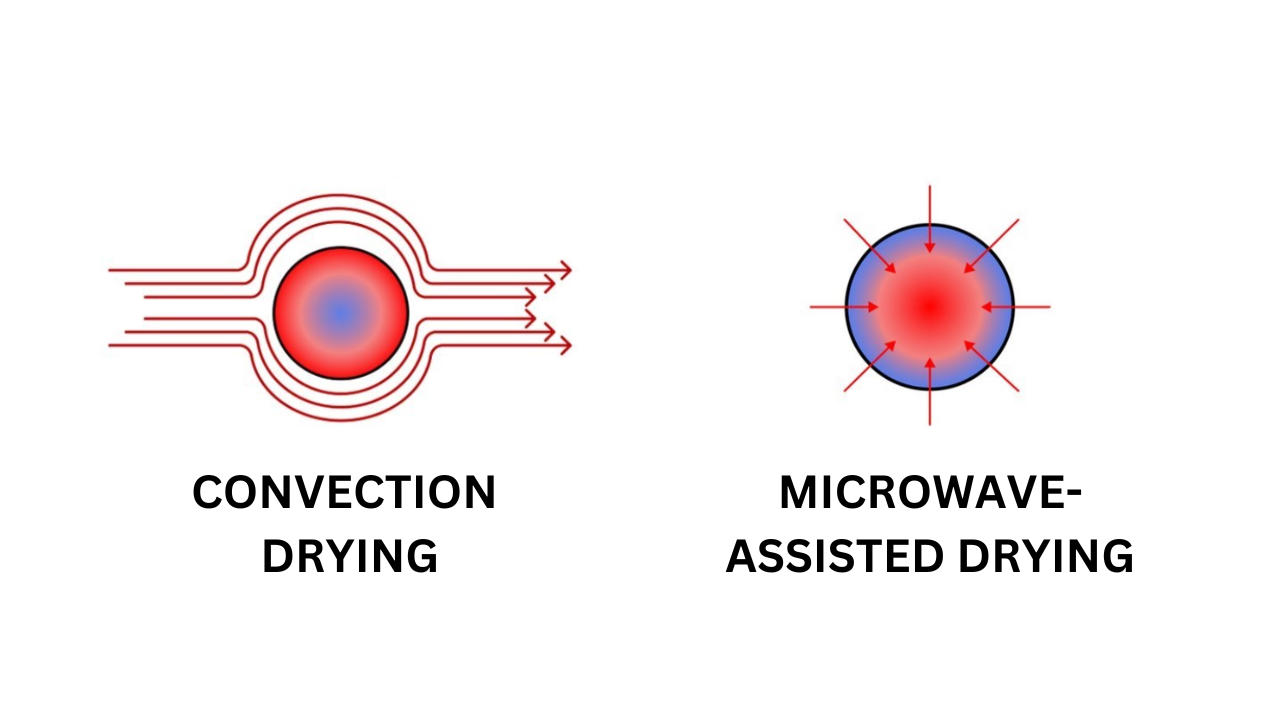

Microwave drying and convection drying both evaporate water, though their heating process differs. Microwave drying penetrates deep into the material using microwave energy, rapidly heating it throughout simultaneously (volumetric drying). Whereas convection drying circulates a heated medium (such as air) around a product, heating the surface of the material and slowly heating to the core (surface-to-core drying). Their different operational parameters and moisture removal process allows convection and microwave drying to create different products.

TIME

Optimizing drying speed is essential in industrial processing to pinpoint potential future bottlenecks, estimate future expansion potential, and ensure optimal product quality. Industrial microwave drying typically has a shorter processing time compared to convection drying. This is because the rapid conversion of microwave energy to heat in the product quickly transfers moisture from the inside out. In contrast industrial convection drying, which relies on heated air for surface-to-core drying, is much slower as it must first heat the surface before the core can begin to heat.

By adjusting the microwave energy being applied, industrial microwave drying can rapidly adjust to changing material moisture for a faster drying process, improving overall efficiency. While industrial convection drying is unable to react quickly to changing moisture levels, which can lead to delays and congestion in production.

In addition, drying time can influence product quality. Quick-drying processes, like microwave drying, can preserve product quality because exposure to high temperatures is relatively short. Slow high-temperature processes, like convection drying, can degrade the material due to prolonged exposure to heat.

END PRODUCT

Not all drying techniques result in the same end product. Individual drying techniques often preserve different characteristics of product quality, like appearance, colors, nutrients, and textures. It’s important to choose a drying technique based on the end product goal, consumer satisfaction, and desired market.

The lengthy exposure of hot air during convection drying can promote oxidation reactions, heat damage, and case-hardening in the material. Microwave drying avoids these issues by providing efficient and fast drying, which preserves both the visual appearance and product quality.

CONCLUSION

Convection drying is often a slower process, which can negatively impact product quality. While microwave drying is a more efficient and quicker process, minimizing the impact of drying on the quality of the product.

CONTACT AN EXPERT

Looking for more information? Contact us to explore how microwave processing can benefit your production process and product quality.