THE VERSATILITY OF MICROWAVE DRYING:

A SINGLE, PRE-, OR POST-DRYING STEP

ALWAYS RAPID, ELECTRIC, AND ENERGY-EFFICIENT

Microwave drying is a rapid, electric, and energy-efficient, tool that can be used as a standalone or pre/post drying step for a variety of applications in the food and industrial sectors. Compared to traditional drying methods, microwave drying can offer significant time and natural gas savings. In addition to operational savings, adding microwave drying to an existing drying process could help develop new products.

BRIEF REVIEW OF MICROWAVE DRYING

A generator converts electric energy to microwave energy and guides it to a chamber through waveguides. In the chamber, the microwaves selectively target polar molecules (like water) within the material (sometimes referred to as volumetric heating as all the whole product volume heats). These polar molecules rapidly vibrate because they’re trying to align to the microwave’s electric field, creating friction between molecules. This friction converts microwave energy into thermal energy, rapidly increasing the temperature of the material and evaporating water.

BENEFITS OF DRYING WITH MICROWAVE

TIME SAVINGS

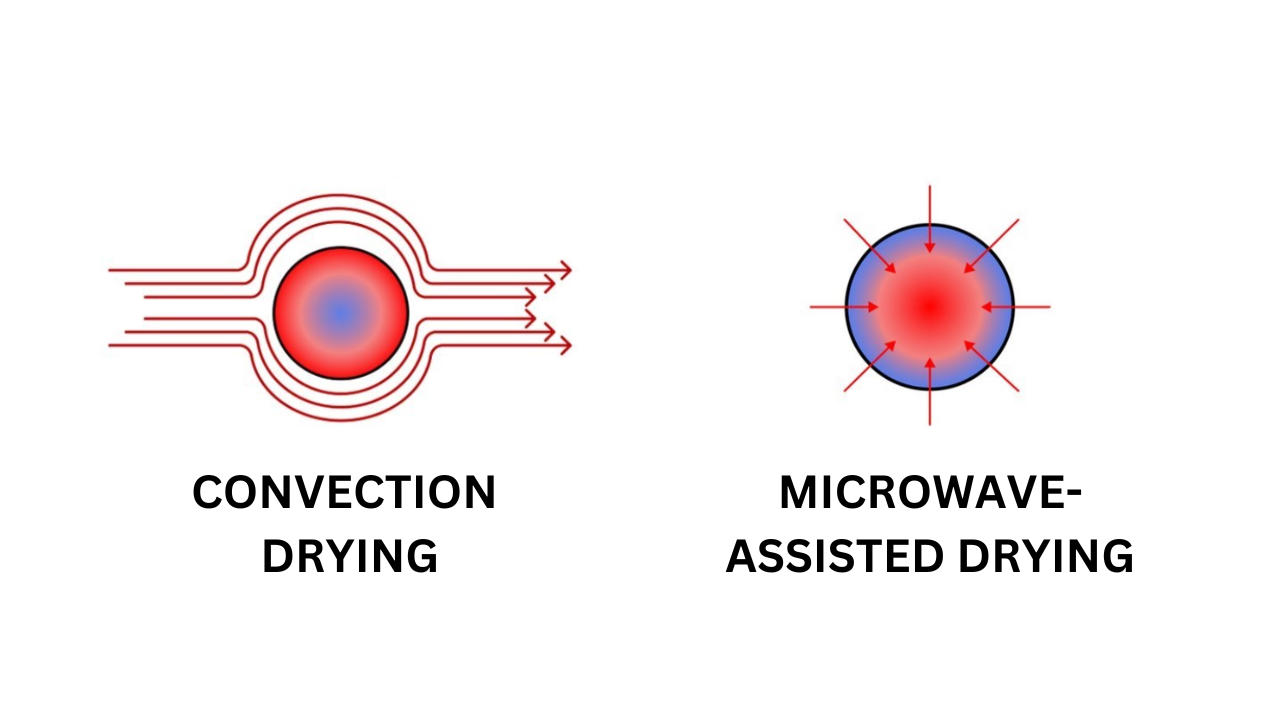

Microwave drying is generally faster than traditional natural gas drying methods, like convection or air drying. This is because microwave drying usually uses energy effectively and directly in the drying process, allowing for faster moisture removal. For instance, microwave energy selectively targets polar molecules within the materials (high energy efficiency), rather than traditional methods that use the surrounding air to heat the outside surface of the material and slowly heat towards the centre (generally low energy efficiency). As a result, drying with a microwave system or adding it as a pre/post-drying step to traditional methods can shorten drying times by using energy efficiently.

Diagram illustrating microwave and convection heating mechanisms. Convection drying dries from surface to core, whereas microwave energy targets polar molecules within the material, allowing for core-to-surface (volumetric) drying.

NATURAL GAS SAVINGS

Similar to how microwave processing used alone or in combination with traditional methods can shorten drying times, it can also save on natural gas usage because microwave drying uses electricity as its energy source. As a result, microwave systems could reduce or eliminate fossil fuel usage from drying (depending on if it’s used as a single or added process). This feature is particularly beneficial for companies focusing on their ESG commitments and reducing their carbon emissions.

The exact savings depend on a multitude of operational parameters and hybrid configurations, like your desired water removal, transition point between systems, specific energy consumption of the existing system, and the cost of natural gas.

EASILY CREATE NEW PRODUCTS

Adding a microwave system as a pre- or post-drying step could allow you to easily develop new products. This is because drying with a microwave system can create differing product textures depending on the material’s starting conditions and upstream processing – an interesting feature in the food industry.

CONCLUSION

Replacing or adding microwave drying to an existing process could offer significant operational and product development opportunities. Microwave drying’s energy efficiency could speed up existing drying processes while reducing natural gas usage, either as a standalone replacement or as an added drying process. In addition, adding a microwave drying process or modifying existing microwave processing parameters could allow you to easily customize your product based on changing market trends.

It’s worth noting that the exact time and natural gas savings from leveraging microwave drying depend on multiple factors like the type of material, current processing parameters, and end product goals.

Contact us to learn more about how microwave drying could benefit your process.