Microwave Drying

Food and Material

NuWave Research

Revolutionizing the Process With Microwave Drying

At NuWave Research, we are global leaders in microwave technology, specializing in advanced microwave systems for both food and industrial materials. With our innovative approach, we harness the power of microwave energy to speed up the drying process while improving energy efficiency and enhancing product quality. If you’re looking to optimize your drying process, discover the benefits of microwave drying and how it outperforms traditional drying methods.

Why Choose Microwave TECHNOLOGY?

Leverage Microwave DRYING

Unlike other heat sources, microwaves heat volumetrically by penetrating deep into the material to heat the whole volume simultaneously. Microwave’s volumetric drying speeds up an otherwise slow process, all while optimizing energy efficiency and improving final product quality. Read our blog post to learn how it compares to a traditional system.

Combining the advantages of microwaves with NuWave Research’s patented techniques allows our equipment to reach high throughputs with capacities from 100kg per hour up to +40 ton per hour and achieve uniform product drying through even energy distribution.

Some Benefits:

Reduced Energy Costs

High Throughput

Faster Drying Times

Premium Products

How does it work?

The Science Behind Microwave Drying

Microwave drying is a dielectric process that converts electromagnetic energy into heat within the product (volumetric heating), leading to water evaporation. Microwaves are generated from electric energy, and directed to material (food or industrial material) in a chamber. Polar molecules in the material absorb the microwaves and try to align their electric field, causing rapid vibration and friction between molecules. This friction converts microwave energy into thermal energy, increasing the temperature of the material.

Overall, the unique process allows for even energy distribution throughout the product, ensuring consistent and uniform drying, whether you’re processing food or industrial materials.

Where can microwaves be applied?

Discover our MICROWAVE DRYING Applications

At NuWave Research, we offer cutting-edge microwave dryers designed for a wide variety of applications. Whether you’re drying food, carbon products, or composite panels, our industrial microwave systems provide high efficiency and customizable solutions to suit your specific needs.

Some drying applications that resulted in fast drying times, superior quality retention, and premium products include:

- Carbon Products: Efficient drying of carbon-based materials

- Composite Panels: Uniform drying of complex composite panels

- Food Industry: Vacuum drying healthy single ingredients like fruit & vegetable snacks

- Materials: Ideal for quickly and evenly drying industrial materials like foam products

What are the machine options?

Microwave DryERS

Our in-house team of microwave experts are ready to deliver an industrial microwave system that will provide the best material handling and processing environment for your product.

PROCESSING OPTIONS INCLUDE:

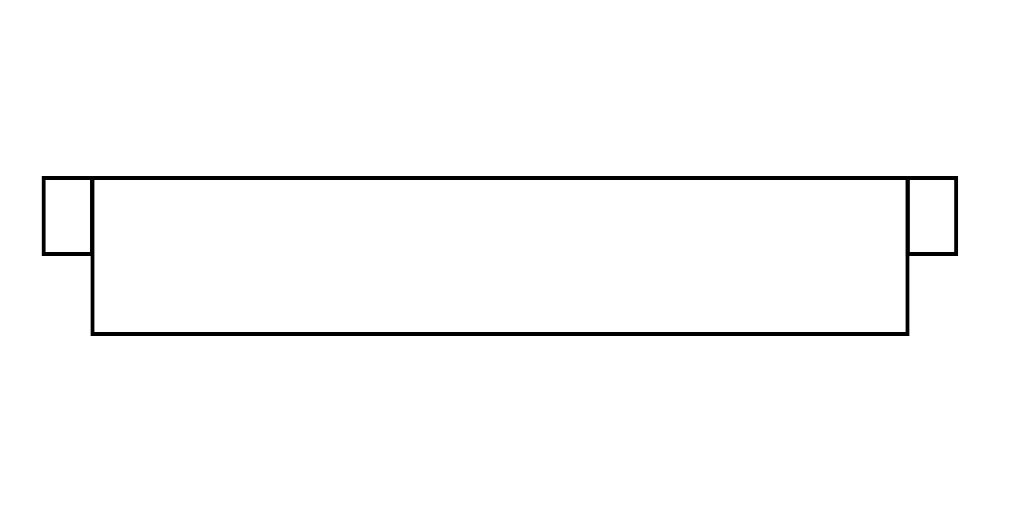

Tray

Available in ambient or vacuum environments.

Perfect for gentle drying of fragile products, such as complex baked goods like cheesecake.

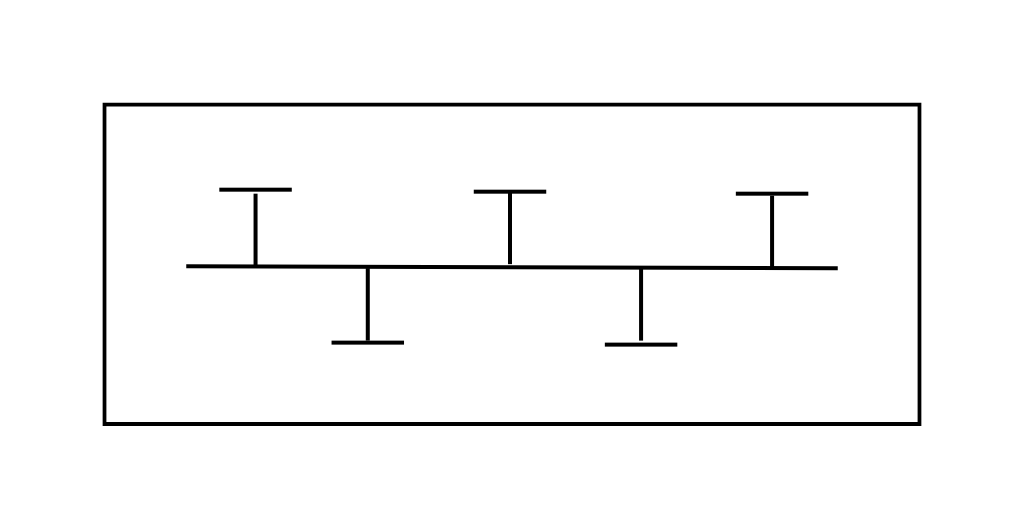

MIXER OR ROTARY DRUM

Available in ambient or vacuum environments.

Ideal for drying loose products or products that can handle mixing or rolling inside a drum.

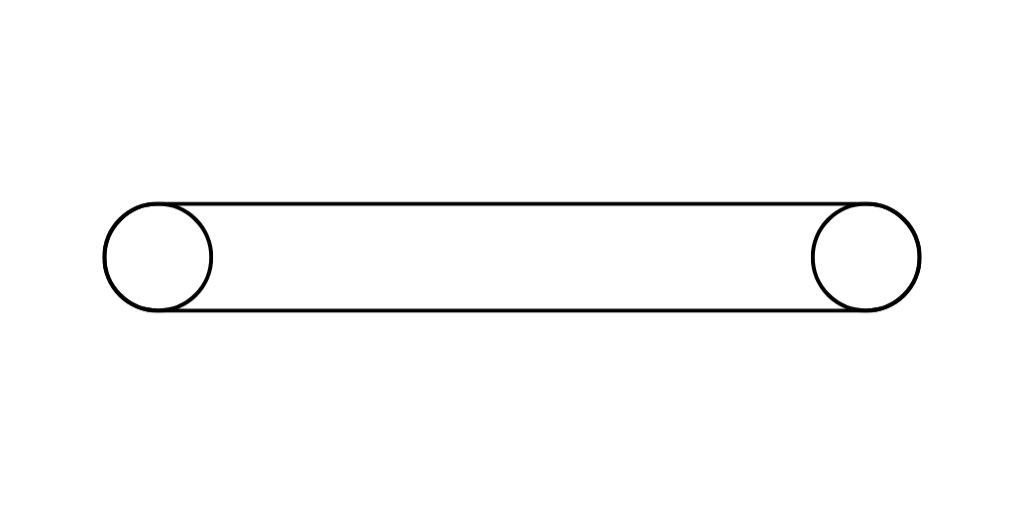

BELT

Available in ambient environments.

Perfect for drying products from thick slurries to powders, to shredded products to panels or slabs.

Talk to a Microwave Expert

Interested in OUR Microwave DRYERS?

Interested in learning more about our microwave techniques and systems?

EXPLORE OUT EXPERTISE

CURIOUS ABOUT NUWAVE RESEARCH?

Curious about NuWave Research and our expertise? Visit our LinkedIn to view some machine updates, blog posts, and employee highlights.