MICROWAVE VACUUM, AMBIENT, AND INERT ATMOSPHERE PROCESSING:

THE INFLUENCE OF ENVIRONMENT ON MICROWAVE PROCESSING

Similar to traditional systems, industrial microwave systems are designed for ambient or vacuum (or even inert atmosphere) conditions depending on the material and end-product goal.

MICROWAVE AMBIENT PROCESSING

Using Microwave in place of traditional heating methods decreases the processing time of products, increasing throughput. This is driven by the efficient energy transfer of microwaves and volumetric heating, as opposed to less efficient methods like convection or infrared drying. Read our blog post to learn more about how convection compares to microwave drying.

Typically, microwave ambient processing is ideal for materials with low heat sensitivity in slab, piece, or granular forms. Some of these materials include:

- Foam

- Pulses: pea protein

- Fruits & Vegetables: Carrots, Blueberries, Cranberries

- Polymers & Plastics

- Rubber

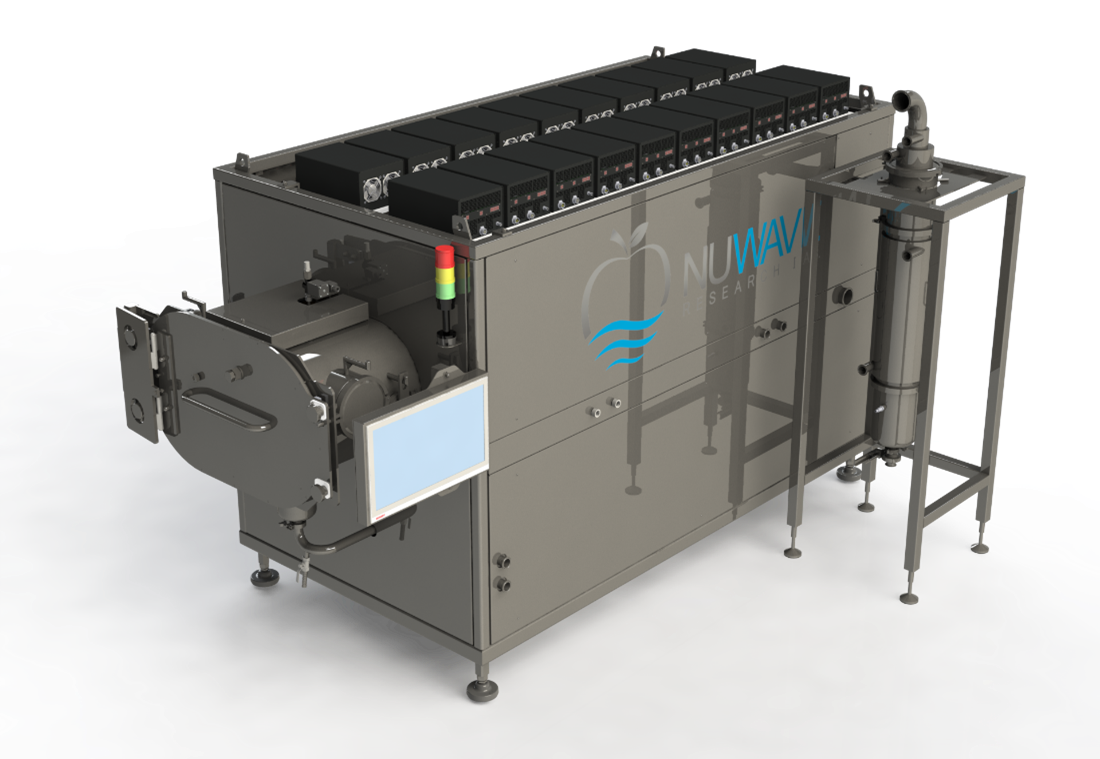

Industrial microwave systems designed for ambient pressures are usually open vessels, like belt- or mixer-based systems. These systems are easily scalable. In the case of belt-based systems, they can be combined with traditional drying methods to create “hybrid” dryers. As a result, this combines the benefits of both traditional heat sources and microwave energy. Examples of our standard microwave systems that can be designed for ambient pressures are Borealis (conveyor-based system) and Titan (paddle-based system).

An example of NuWave Research’s Borealis system, a conveyor-based dryer. This system is ideal for ambient environments and processing panel, granular, and powder products.

MICROWAVE VACUUM PROCESSING

Adding vacuum to microwave processing is ideal for temperature sensitive materials and preserving material quality. Using vacuum lowers the boiling point of water, allowing for rapid water removal at low temperatures (gentle drying).

For food products, microwave vacuum processing preserves the fresh colors, tastes, and aromas, while potentially adding a crispy texture and satisfying crunch. For chemicals and other materials, it can help increase the purity of the final product and reduce product damage from overheating that would occur with traditional drying methods.

Usually, microwave vacuum processing is the best fit for powder, granular, sliced, diced, shredded, and materials that require gentle handling. Some of these products include:

- Insects: Crickets, Black Soldier Fly Larvae

- Nutritional Supplements

- Fruits and Vegetables: Apples, Sweet Potatoes, Pineapple

- Baked Goods: Cheesecake, Donuts

- Ground/Powdered Ingredients: Sea Salt, Yeast

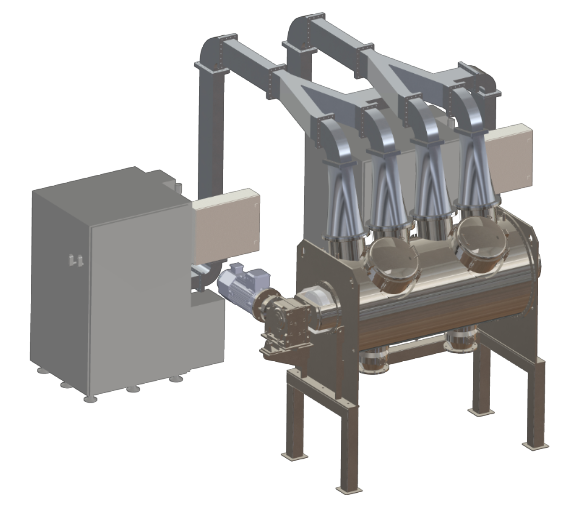

Industrial microwave systems designed for vacuum environments are closed systems that can be batch or continuous, less flexible when scaling, and restricted in hybrid processing options. As a result, platforms for this type of design include tray-based (like Chimera or Kraken machine) and mixer-based systems (like Titan machine).

Chimera, NuWave Research’s tray-based system ideal for vacuum processing powder, liquid, slurry, granular, sliced, diced, and shredded products, or materials that require gentle handling.

MICROWAVE INERT ATMOSPHERE SYSTEMS

Some materials require, or could benefit from, the use of inert gas atmospheres during microwave processing. This prevents unwanted reactions and oxidation which can cause either contamination or product degradation. For instance, the quality of some products is improved by microwave processing under nitrogen atmosphere due to the absence of other reactive gases, like oxygen.

Microwave systems capable of inert atmosphere environments are closed systems with batch processing or open systems. Ultimately, the system design depends on the product and process requirements. Tray- (like Chimera machine) and mixer-based systems (like Titan machine) can be configured to process under inert atmosphere environments.

An example of Titan, NuWave Research’s paddle-based system ideal for vacuum or inert gas environments processing of powder, granular, sliced, diced, and shredded products, or materials that handle gentle mixing.

CONCLUSION

Processing using vacuum, ambient pressure, and inert atmosphere (or some combination) with microwave is another powerful tool for operations looking to improve efficiency and product quality. Whether that’s combining microwave’s rapid and energy-efficient processing with ambient conditions for standard products, with vacuum environments when gentle treatment is important, or with microwave inert atmosphere for better product quality. Ultimately, this technology can be applied to unlimited applications.