ELECTROMAGNETIC DRYING: IR AND MICROWAVE TECHNIQUES

SOLUTIONS FOR DIFFERENT INDUSTRIES

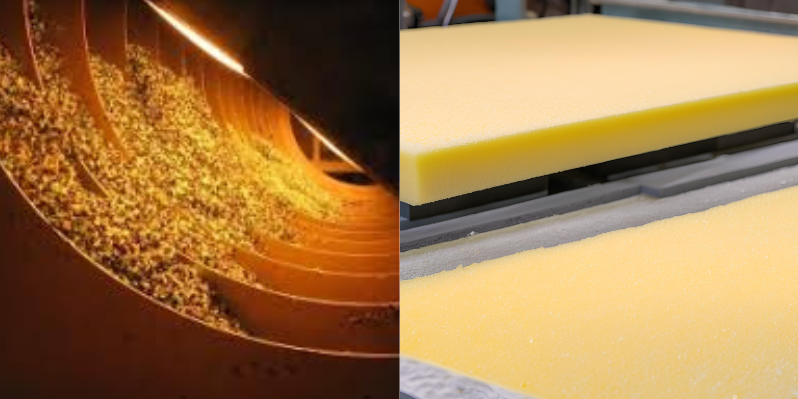

Electromagnetic drying encompasses infrared (IR) and microwave drying techniques, but they utilize different wavelengths of electromagnetic energy to dry materials. Microwave drying, which uses microwaves generated from electric energy, is effective for uniform and rapid heating of materials with varying thickness. While IR drying emits infrared waves from gas or electric energy, and can be ideal for uniformly heating thin materials. These technologies are widely used but a further understanding of their drying methods, operations, and wavelengths is key in selecting the right solution.

Diagram illustrating IR and microwave wavelengths in the electromagnetic spectrum.

How do THEY work?

Both microwave and IR are energy-efficient drying techniques as they directly transfer energy (microwave or IR waves) to the molecules without significantly heating the surrounding air.

IR DRYING

In IR systems, IR waves are generated from electric or gas energy and emitted into a chamber from emitters. A few types of emitters are quartz tubes, ceramics, and gas catalytic heaters. Molecules in the material absorb the IR waves causing them to vibrate more rapidly, increasing their kinetic energy. This kinetic energy is converted into thermal energy, increasing the temperature of the material.

MICROWAVE DRYING

In microwave systems, microwaves are generated from electric energy in magnetrons and direct into a chamber via waveguides. Polar molecules in the material absorb the microwaves and try to align to their electric field, causing rapid vibration and friction between molecules. This friction converts microwave energy into thermal energy, increasing the temperature of the material.

WAVELENGTH PENETRATION DEPTH

The energy penetration depth changes with wavelength for both technologies. For instance, larger wavelengths penetrate more than smaller wavelengths. Microwaves have longer wavelengths from 1 millimetre to 1 meter, while infrared wavelengths range from 1 millimetre to 700 nanometres. As a result, IR drying can heat the bulk of the material, but it cannot volumetrically heat material thicker than a few millimetres. Whereas microwave drying is a volumetric process that can penetrate deeper into material (depending on the material) for uniform heating.

IR and Microwave Drying Applications

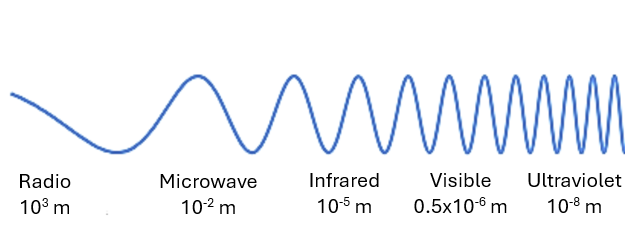

IR drying is limited to material a few millimetres in thickness due to its wavelength. Whereas microwaves can penetrate material up to a few inches depending on the wavelength. As a result, IR drying is great for roasting food products and curing thin materials like paint, paper, and textiles. This is where IR can selectively act on the surface of a product, so energy is not wasted heating the rest of the bulk. Microwave drying is ideal for applications that require uniform heating or relatively thicker materials like foam, shelf-stable food products, and composite panels.

Ideal applications for IR and microwave drying: infrared drying thin food on the left, microwave drying foam on the right.

IR and Microwave Drying Speed

Optimizing drying speed is essential in industrial processing to maintain product quality, increase throughput, and enhance overall process efficiency. IR and microwave drying operations are both fast processes because of their efficient energy transfer compared to traditional methods. This means little to no time is required to begin heating with IR and microwave systems. Although microwave drying is generally faster. Microwaves target polar molecules throughout the material (a process known as volumetric heating) and have deeper material penetration ability. This allows for rapid moisture removal from the inside out, as opposed to the slower surface-to-core heating caused by minimal penetration into the material with IR (similar to conventional drying).

Operational Insights into IR and Microwave Drying

Both systems can be used as a standalone step or added to traditional methods for pre- or post-processing. In addition, both also offer high energy flexibility during operations as they can adjust their energy by zone to accommodate processing speed, and in-coming material temperature.

ENERGY SOURCE

Microwaves systems are fully electric, while IR systems can be gas or electric powered. Gas powered IR systems require more permits and professional installation services like a gas line connection compared to electric systems. Fully electric systems, like those using microwave energy, offer green emissions-free operation that require little to no permitting. As a result, replacing or combining traditional methods with microwave or electric IR systems could lead to reduced fossil fuel emissions.

SYSTEM CONFIGURATION

Regarding system configuration, IR and microwave systems have smaller footprints with minimal ducting as they require significantly less air handling than traditional methods. IR and microwave drying operations can be batch or continuous and offer various processing options depending on the material and application. For instance, conveyor-based systems are generally for processing flat materials, and mixer/rotary paddle-based systems can be used for slurry or granular materials.

CONCLUSION: Overview of IR and Microwave Drying

In this blog, we examined how IR and microwave drying applications and material penetration depth differ. This is primarily due to differences in wavelengths. IR waves are shorter compared to microwaves, and as result, cannot volumetrically heat material thicker than a few millimeters.

This makes IR drying ideal for roasting food products and curing thin materials like paint, paper, and textiles. Alternatively, microwave drying is a volumetric process that penetrates and completely dries material of varying thickness. This makes microwave drying ideal for applications that require uniform heating or relatively thicker materials. For example, some ideal applications include foam, shelf-stable food products, and composite panels.

In terms of operations, they both offer small footprints and various system designs, but their processing speed differs primarily due to differences in wavelength penetration depth. In addition, gas-powered IR systems could lead to higher emissions and installation costs compared to microwaves.

For optimal results, it is important to consider your specific material characteristics, product goal, and drying requirements when choosing between these technologies. In some cases, a combination of drying methods might provide the best outcome. Contact us to learn more about microwave drying and its applications.