MICROWAVE HEATING

FAST, EFFICIENT, AND COMPLETE HEATING

HOW DOES IT WORK?

tHE SCIENCE of Microwave Heating

Microwave heating is a process where dielectric molecules oscillate in response to exposure to microwaves, generating heat through friction. Depending on the energy input, our microwave systems can generate heat from 50°C up to 2000°C rapidly throughout the material because all the energy is transferred to the material rather than the surrounding air.

HOW DOES IT COMPARE?

DISCOVER VOLUMETRIC HEATING BY MICROWAVE

Microwave heating can be used as a single step to reach a target final temperature, or as pre- or post-heating step to speed up an otherwise slow high-temperature process. Unlike traditional methods that slowly create thermal gradients by heating surface to core, microwave processing is volumetric, rapid, and energy-efficient. Where traditional methods are fossil fuel-based, pre-heating with microwaves could reduce or eliminate the need for fossil fuel-based product heating.

Combining the advantages of microwave with NuWave Research’s techniques allows our systems to reach high throughputs, with capacities from kilograms per hour up to +100 ton per hour, and achieve uniform heating by evenly distributing the energy. With the ability to alter the applied energy instantly, NuWave Research’s microwave systems can adjust rapidly to changing product flow, meaning consistent final product temperature even if the incoming temperature varies.

SOME BENEFITS OF MICROWAVE HEATING INCLUDE:

High Throughput

Reduce Energy Usage

Faster Heating Time

Consistently Heated Product

WHERE CAN MICROWAVE BE APPLIED?

OUR Microwave Heating APPLICATIONS

Microwave can be applied in solutions for heating a wide range of products and forms (slurry, liquid, powder, etc). The efficiency of microwave in a specific application is based on how the material interacts with microwaves.

Some of the applications that resulted in fast and efficient heating include:

-

Chemical Formulations

-

Plastics

-

Coal

-

Food & Snack Products

-

Foam

Curious about your material?

Reach out to one of our experts to learn more about our microwave processing and discuss your application!

SINTERING, SMELTING, CALCINATION, PYROLYSIS

RAPID HIGH TEMPERATURE Microwave HEATING

Microwave processing is well-suited for high-temperature processes up to 2000°C and beyond, such as smelting ores for metal extraction and pyrolyzing waste. This is because microwaves can help accelerate specific chemical and physical changes in materials faster than traditional methods by selectively interacting with polar molecules, and heating volumetrically. This technique not only speeds up processes but can also help homogenize the final product through uniform heating – like removing impurities in carbon products.

Some common applications of high-temperature microwave processing include:

-

Carbon Products

-

Limestone

-

Cement

-

Ceramics

-

Ore processing

-

Clay products

WHAT ARE THE MACHINE OPTIONS?

MICROWAVE HEATING SYSTEMS

Our microwave techniques, expertise, and in-house resources offer opportunities to customize our system’s processing based on your end-product goal and system requirements.

PROCESSING OPTIONS INCLUDE:

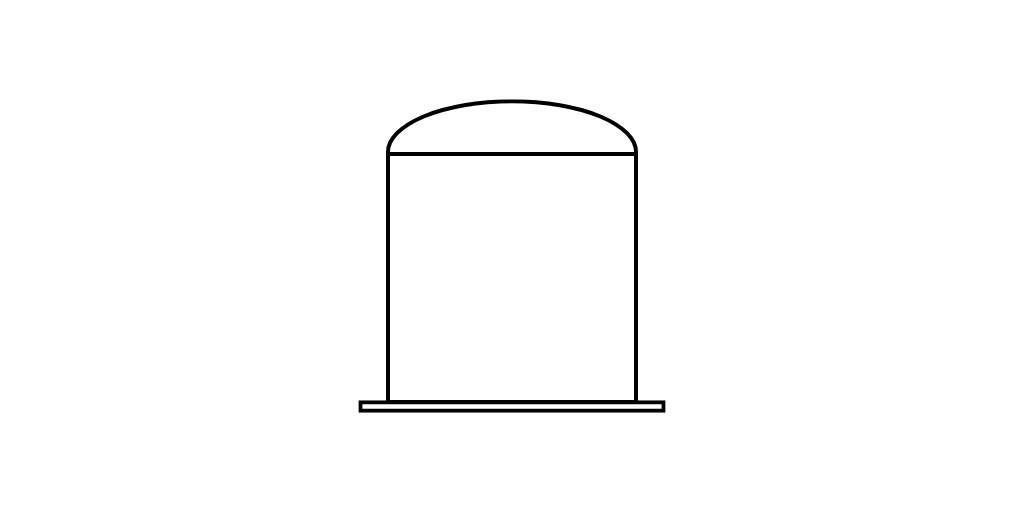

REACTOR

Available in ambient environments.

Perfect for liquid and slurry products with a wide range of solvents, like liquid chemical formulations.

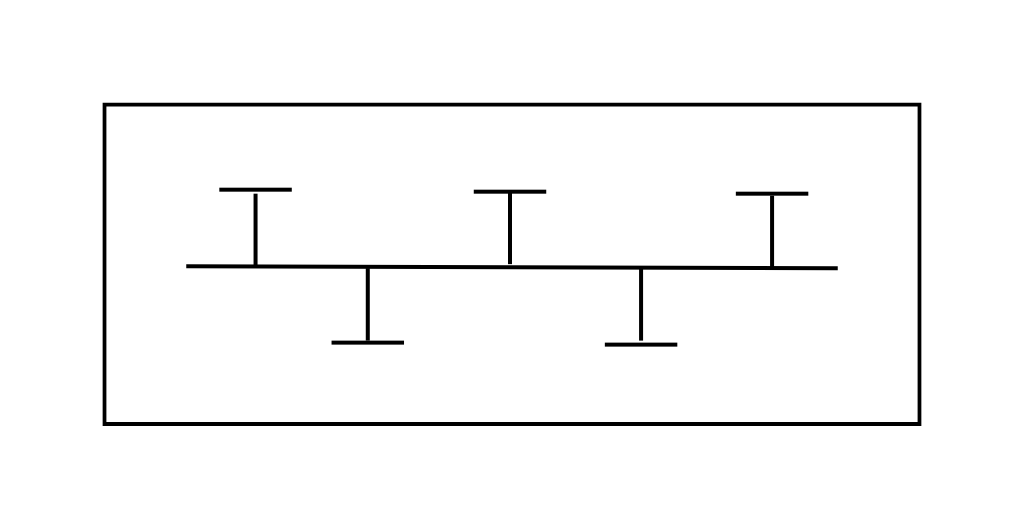

MIXER OR ROTARY DRUM

Available in ambient or vacuum environments.

Ideal for drying loose products or products that can handle mixing or rolling inside a drum.

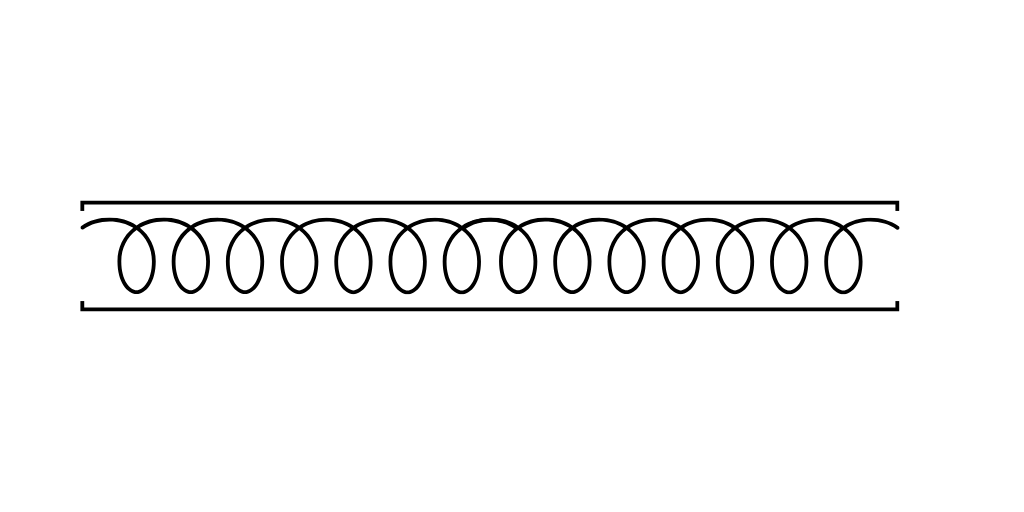

CONTINUOUS FLOW FOR LIQUIDS

Available in ambient environments.

Perfect for liquid products with a wide range of solvents on an industrial scale, like plant flavors and fragrances.

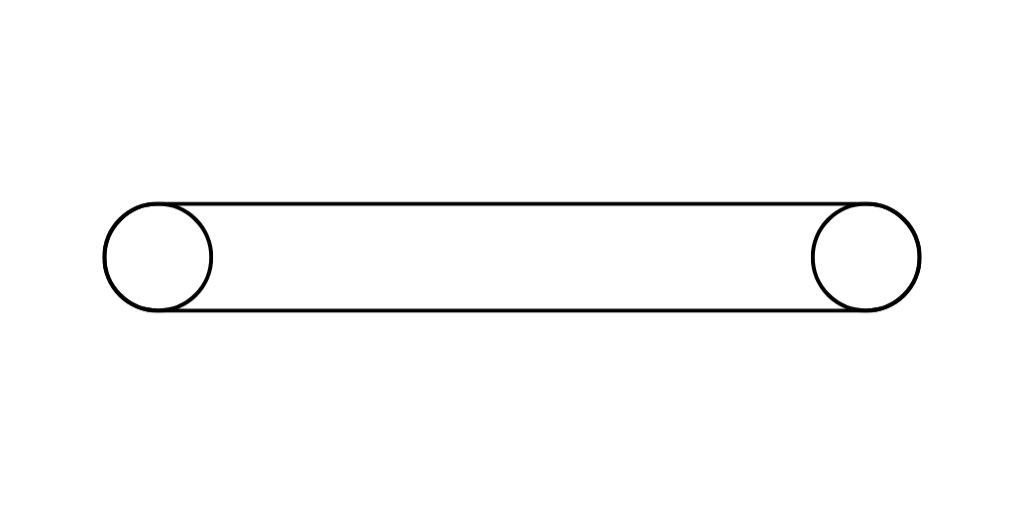

BELT

Available in ambient environments.

Ideal for drying products from thick slurries to powders, to shredded products to panels or slabs.

INTERESTED IN MICROWAVE HEATING?

Talk to an Expert

Curious about our microwave technology and the best industrial microwave system for your application?

Curious about NuWave Research?

Visit our LinkedIn Page

Stay-up-to date with some of our news, blog, and client highlight posts.